The process of making a machine

Production stages, from idea to final product

Idea

The client presents his idea and specific needs so that we can understand his goals and expectations. This includes a brief project description, budget and key requirements.

Concept

Designing a process to automate existing processes involves identifying tasks that are frequently repeated or prone to errors. By analyzing each step within the process, it is determined which activities can be automated.

3D design

3D design enables a visual presentation of the solution concept, including a detailed view of the equipment and how the system was designed. Through 3D models, the team can accurately view all system components, check their functionality in space and identify potential obstacles before implementation.

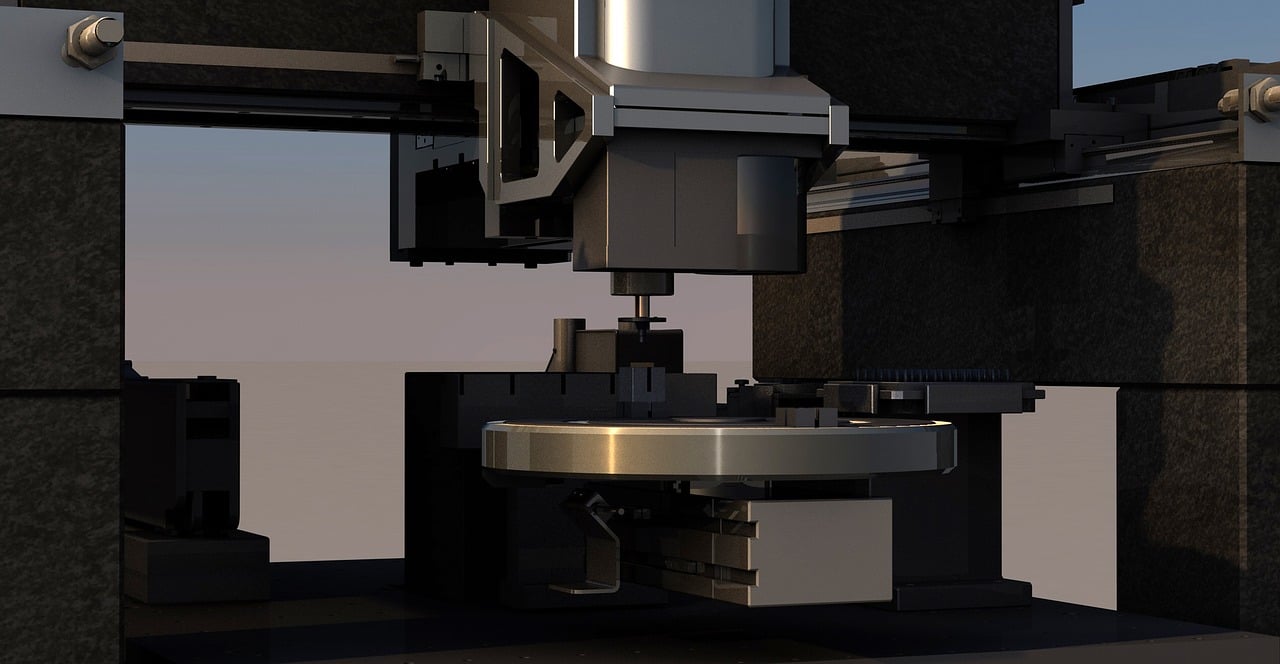

Design - Production

In the design or production phase, the actual production of the machine begins according to the previously defined instructions and specifications of the client. Engineering and manufacturing teams use 3D models and technical drawings as guides for accurate component fabrication, assembly and testing. During this process, it is ensured that every part of the machine meets the standards of quality and functionality that the client has demanded.

Testing and software

In the test and software phase, the machine is first tested inside the factory through a process known as a “DRY RUN” – running the machine without using actual material. The aim of this test is to check the functionality of all components, their mutual interactions and the software control over the machine. During the "DRY RUN", engineers carefully monitor the operation of all systems in order to detect and correct any problems in operation or software code.

Delivery of the finished product

The final step is the delivery of the finished product, where the machine is transported and installed in the space provided for its operation. The final testing of the machine is done, now with real material and in real working conditions. During this test, it is checked how the machine functions in a specific environment and interacts with all necessary resources.

Location

Drage Karamana BB,

75000, Tuzla

Bosnia and Herzegovina

Contact us

+387 63 962 024

+387 62 398 269

info@dpm-atec.com

Working hours

MONDAY - FRIDAY

08:00 – 16:00

SATURDAY AND SUNDAY CLOSED